By implementing IATF16949, customer-centric, process oriented, continuous improvement, prevention oriented, and full staff participation, we ensure that product quality continues to meet standards and meet customer requirements.

Using the QMS quality management system to link quality management activities such as IQC, IPQC, OQC, non-conforming product handling, customer complaint management, quality issues, preventive measures, etc., to achieve quality traceability.

IATF16949 Certification

By implementing IATF16949, customer-centric, process oriented, continuous improvement, prevention oriented, and full staff participation, we ensure that product quality continues to meet standards and meet customer requirements.

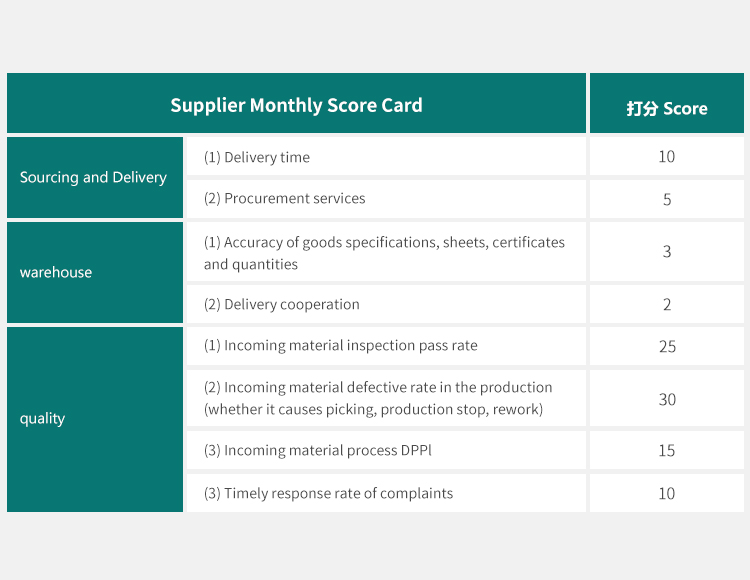

Supplier KPI

Establish a supplier performance evaluation mechanism and conduct monthly scoring assessments. Drive suppliers to improve quality, delivery, and service, thereby promoting the improvement of our product quality.

Advanced processing equipment

Advanced processing equipment ensures that the processing accuracy meets the standards

Precise measuring equipment and instruments

Precise measuring equipment and instruments ensure reliable measurement

Quality Training

Standardized, electronic, and video based employee training helps employees better and faster grasp quality standards and operating methods.

IPQC

Strict online testing and inspection to ensure that each product meets the requirements

OQC

Factory performance testing and experimentation to ensure that product performance meets customer requirements

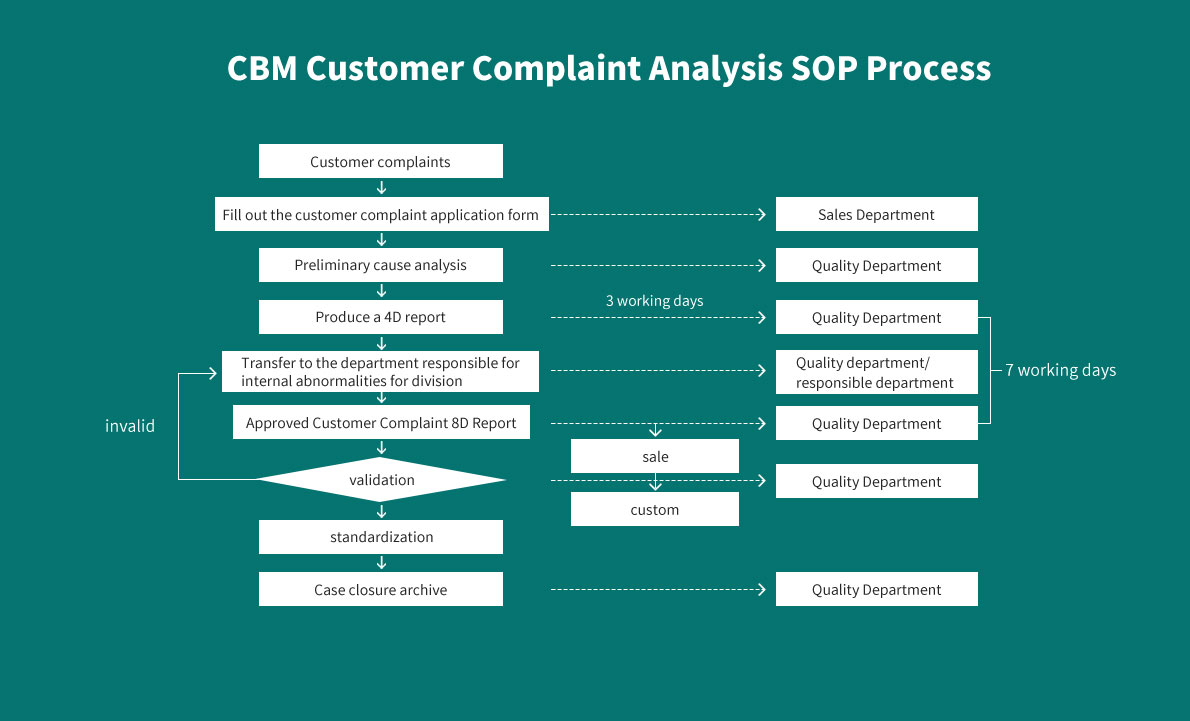

Customer Complaints

Standardize the customer complaint handling process, set templates through the QMS system, promptly address customer concerns, and effectively develop preventive measures.